About the rupture disk

What is Rupture Disk?

If a weak spot is provided in advance in a closed container or part of piping, when the internal pressure rises to a certain level, only this part is destroyed and the internal pressure is released, and the other parts are protected.The weak spots are given shapes, dimensions, pressures, temperatures, etc. and are referred to as Rupture Disk (rupture disks).

Rupture Disk is usually used as a safety device to protect the sealed containers, equipment, piping, etc. of various brands such as chemical and nuclear power from the danger of excessive pressure caused by mechanical mishandling, runaway chemical reaction, fire inside and outside the container, etc.

There are various types of safety devices. However, there are problems for sealing during operation.

On the other hand, Rupture Disk is very effective for preventing the risk or waste of flammable, toxic, expensive gases and radioactive fluids from leaking.

In addition, the rupture disk unit is used not only for discharging excessive pressure, but also for pilot plants and experimental equipment as a sudden valve that opens instantaneously under preset conditions (temperature, pressure, time, etc.).

Spring-type safety valves, which are commonly used as safety devices, have a blow-off pressure.Rupture Disk is distinguished as a safety device with no blow-off pressures, and is used in many ways as a safety device and a device that replace (replace) or combine (combine) a spring-loaded safety valve.

This is a safety device and device that prevent damage to sealed equipment and equipment, such as pressure vessels, piping, and ducts, due to excessive pressure.

When the pressure inside the sealed equipment or equipment rises above this level, the ultra-thin metal plate (disk) ruptures to eject fluid and reduce the pressure.

Features of rupture disks

Point 1

Rapid pressure relief rate

Point 2

There is no leakage

Point 3

Best suitable for high viscosity and fixative fluid

Point 4

Corresponding to corrosive fluid

Rupture Disk configuration

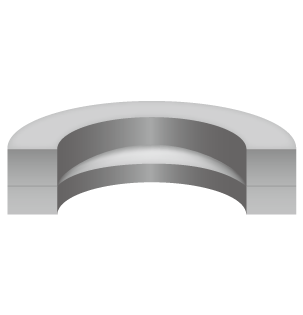

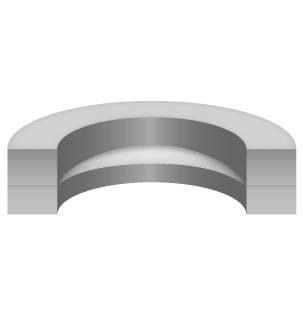

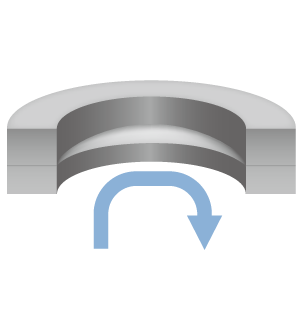

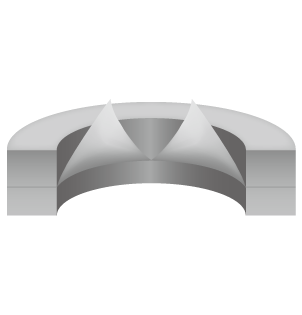

Disk

Parts of a metal plate that burst at the specified pressure and temperature.This product has both the function of adjusting the burst pressure and sealing.The disc material for the composite type is usually PTFE (adjustment of the burst pressures of the composite type is performed using slit discs).

Holder

This part securely fixes the disc.If the disc is not secured securely, the Rupture Disk may change the stresses applied to the disc and the burst pressures.Therefore, a special holding tool is required.

Slit disk

This is a dome-shaped, radially grooved metal part used in composite molds.This groove adjusts the burst pressure.

Vacuum support (V support)

This part is used to prevent deformation and buckling of the disc by attaching the disc in such a manner that it is superposed on the upstream side of the disc when the inside of the equipment is under vacuum or back pressure.There are two types of V-support: one that ruptures with the disk and the other that does not need to be replaced. Usually, the V-support is used for vacuum specifications of a tensile type.

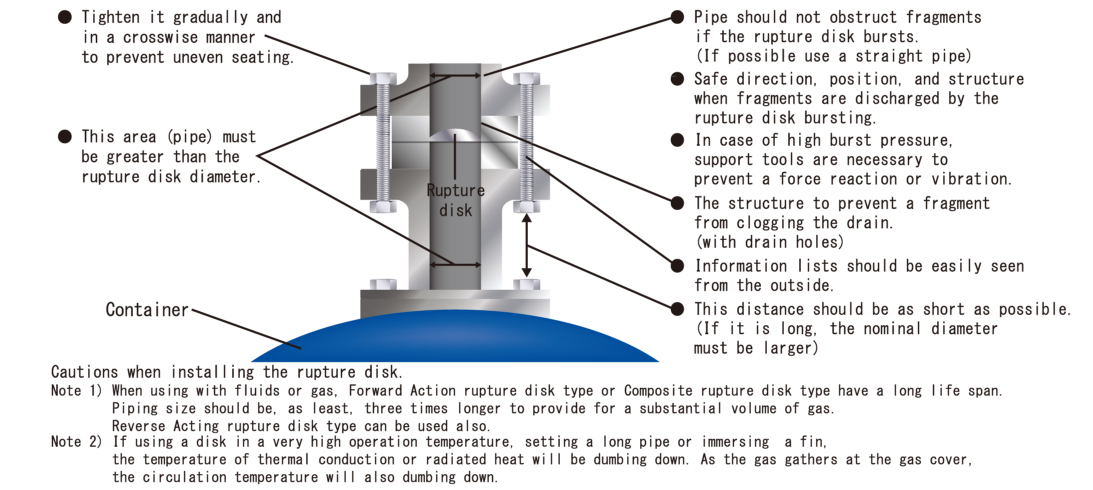

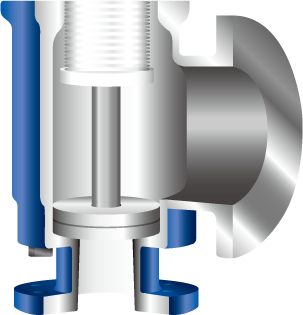

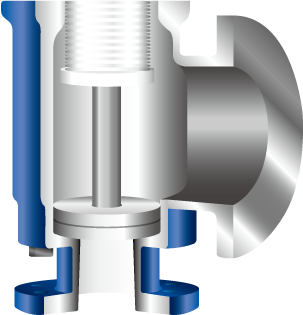

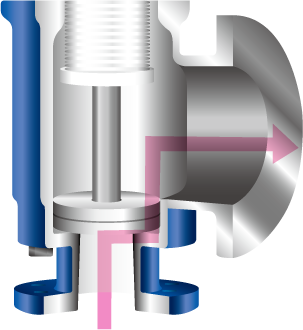

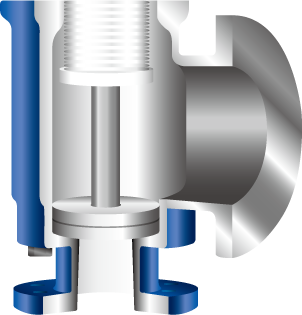

Installing the rupture disk independently.

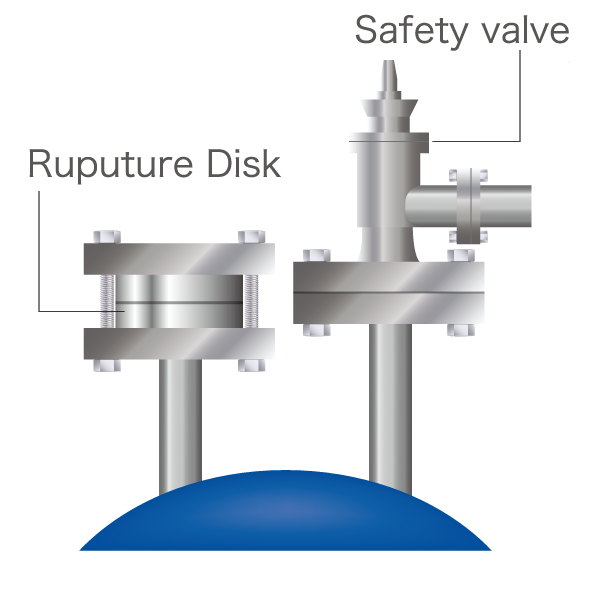

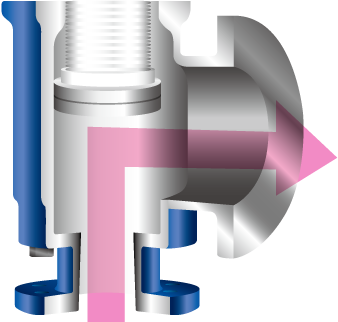

When the Rupture Disk and safety valve are installed in combination.

- Combination

-

Paralleled

Rupture Disk = Safety valve

- Purpose or Effect

-

- Prolongation of Rupture Disk life

- Countermeasures against malfunction of the safety valve

- Combination

-

Series

Rupture Disk → Safety valve

- Purpose or effect

-

- Prevention of corrosion on the inlet side of the safety valve, entry of foreign matter, and leakage

- Prevent unnecessary fluid spills when the Rupture Disk ruptures.

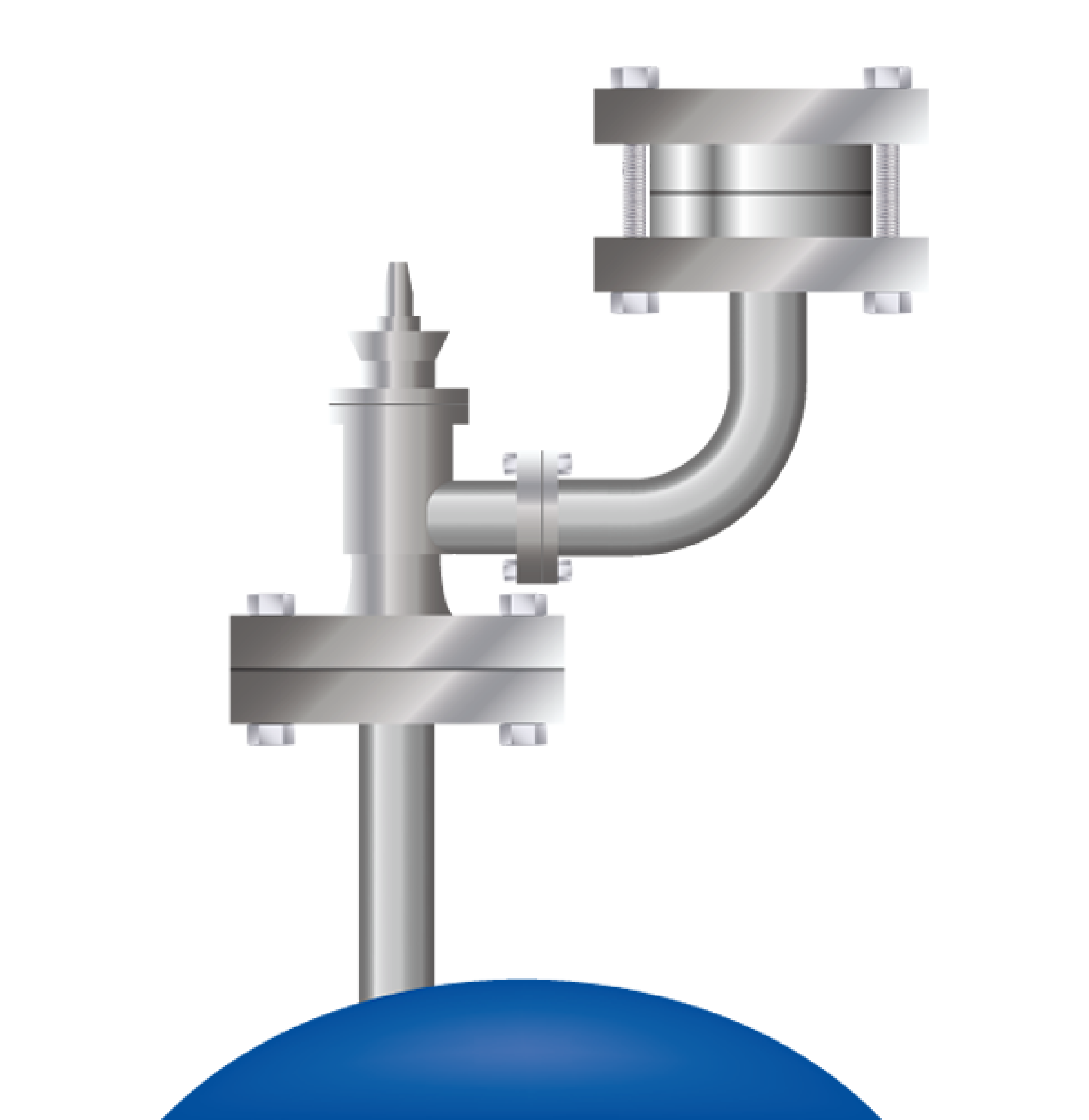

- Combination

-

Series

Safety valve → Rupture Disk

- Purpose or effect

-

- Prevention of leaks

- Prolongation of Rupture Disk life

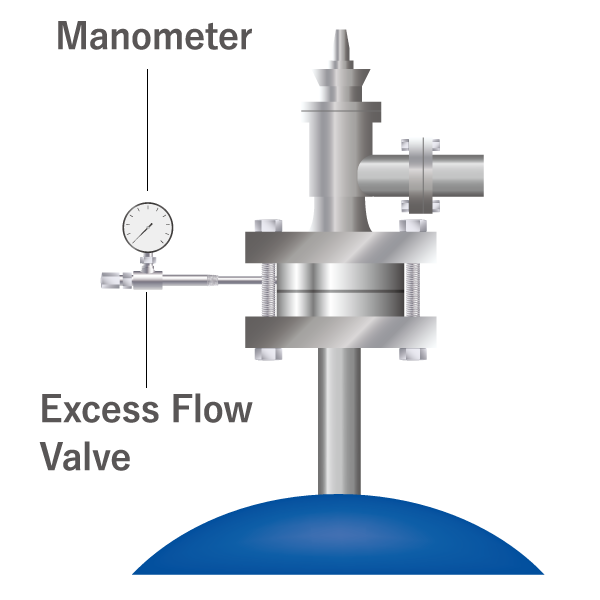

- Combination

-

Series

Rupture Disk → Rupture Disk

- Purpose or effect

- For highly corrosive fluids

If a pinhole occurs due to erosion of the upstream Rupture Disk, it is detected by a pressure gauge, etc. to prevent leakage and protect the vessel against abnormal pressure until the Rupture Disk is replaced.

Comparison of operation with safety valve

Advantages of rupture disks

- There is no leakage.

- Release faster

- Reliable operation (bursting) is several to several tens of msec.

1

For example

- Safety valve

-

- Initial pressure (e.g. 0.45MPa)

- Blow pressure (e.g. 0.50MPa)

- Blow stop pressure (e.g. 0.40MPa)

- Rupture Disk

-

- Burst pressure (e.g. 0.50MPa)

2

During operation

- Safety valve

-

- Primary pressure (e.g. 0.40MPa or less)

- Rupture Disk

-

- Primary pressure (e.g. 0.40MPa or less)

3

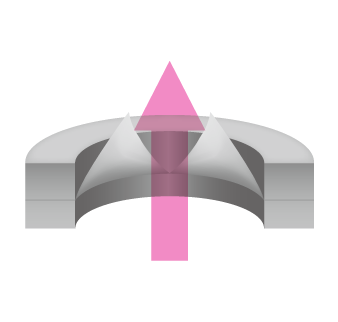

When pressure rises (blow start pressure)

-

Safety valve

Begin to leak

-

- Primary pressure (e.g. 0.45MPa)

Start-to-discharge pressure

- Primary pressure (e.g. 0.45MPa)

-

Rupture Disk

No leakage

-

- Primary pressure (e.g. 0.45MPa)

4

When pressure rises (blowout pressure is exceeded)

-

Safety valve

Fully open

-

- Primary pressure (e.g. 0.50MPa or more)

(Blow pressure or more)

- Primary pressure (e.g. 0.50MPa or more)

-

Rupture Disk

Bursting

-

- Primary pressure (e.g. 0.50MPa or more)

(Blow pressure or more)

- Primary pressure (e.g. 0.50MPa or more)

5

After operation

-

Safety valve

Valve closing

-

- Primary pressure (e.g. 0.40MPa or less)

(Reseating pressure)

- Primary pressure (e.g. 0.40MPa or less)

-

Rupture Disk

Opening after rupture

-

- Primary pressure (e.g. 0.40MPa or less)